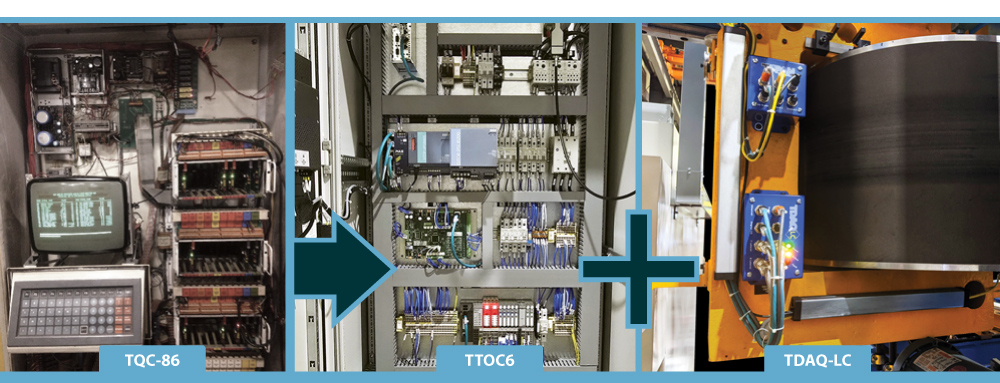

Are you still running your Tire Uniformity machines with antiquated TQC controllers?

Upgrade to CTI’s Linux-based TTOC6 and increase measurement accuracy, reduce machine downtime and maintenance costs, optimize force and runout grinding, and seamlessly share information with external plant systems, such as QA data, recipes, waveforms, and energy consumption. We offer a TTOC6 controller that is packaged for direct replacement of a TQC-86 or TQC-PC panel and can be installed and fully commissioned in only 4-5 days!

- No more Windows® crashes or constant cybersecurity threats - single Linux IPC for all machine options (Uniformity, Geometry, Marking, Grading, Grinding, etc). It uses a minimal, stripped-down version of Linux to reduce its security footprint to only those functions required by the machine controls.

- Improved measurement accuracy using the TDAQ (Tire Data Acquisition) product family, which makes decisions on its 24-bit A/D channels and its digital I/O at a blazing 16,000 Hz.

- TTOC6 contains our WVC software, a proprietary way of collecting, evaluating and correcting tire uniformity waveforms providing consistent measurement results even when there are disturbances in the inflation system or when additional warmup is needed to stabilize the loadcell channels.

- TTOC6 includes tire traceability, by barcode, through each station of a uniformity machine.

- TTOC6 contains many patented optimization algorithms that support both shoulders and center (full face) grinders for grinding radial and lateral force (incl. Conicity), radial runout, and localized tread bumps/dents/dips.

- TTOC6 can replicate communications to the existing TQC machine PLC (e.g. 48-96 digital I/O points) so that minimal PLC changes are needed as part of the upgrade.

- TTOC6’s open architecture allows easy integration of barcode readers, marking systems, sorters, etc. It also allows the sharing of information with external databases, MES systems, and other PLCs.

- TTOC6 delivers robust, enterprise-level remote support. CTI’s dedicated staff of experienced engineers can view the same screens as displayed at the machine through our client app, and direct plant personnel with its integrated CHAT interface.

Upgrade to the latest control technology with TTOC6 + TDAQ

- Fewer electronic parts, less points of failure, and better reliability

- Automatic “Maintenance Reminders” for machine upkeep

- Simplified field wiring

- Data acquisition located closer to the source produces stronger and cleaner signals to bring about a substantial increase in resolution

- Machine visualization screens convey tire position and machine status "at a glance"

- Real-time and oscilloscope plotting modes for all analog and digital (incl. PLC) channels

- Real-time production & maintenance statistics display on demand

- Action Viewer tracks all configuration/calibration changes to TTOC6 by user/date/time

- Inflation Optimizaton software (TIO) software that monitors the machine's air regulation performance to quickly stabilize tire inflation to the desired recipe value

- Tire motion algorithms, along with WVC and TDAQ, allow a machine to test, mark, and sort more than 3 tires every minute, while maintaining industry-required measurement repeatability

Remanufacturing

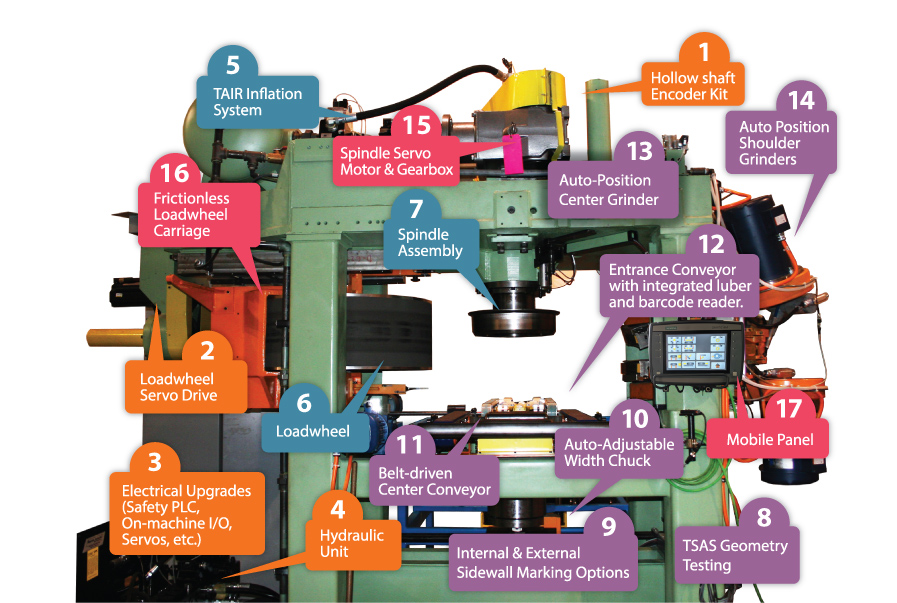

Why stop at upgrading to our TTOC6 Controller? The Poling Group offers over 30 additional options for upgrading any 4-post Tire Uniformity Machine.

The Poling Group offers customizable solutions that help you meet your production targets in the most cost-effective way. Along with our TTOC6 controller upgrade, we offer mechanical and machine component upgrades that help you meet the demands of a constantly changing product mix and OE customer requirements.

A small upgrade investment creates a large machine improvement!

The Poling Group offers more than 30 different machine & tooling options and upgrades that improve testing and production through various means. Below is a sampling of option & upgrades to improve your testing results immediately. Remanufacturing requires previous Tier1 and Tier2 upgrades.

1. Hollow Shaft Encoder Kit

2. Loadwheel Servo Drive

3. Electrical Upgrades

4. Hydraulic Unit

5. TAIR Inflation System

6. Loadwheel

7. Spindle Assembly

8. TSAS Geometry Testing

9. Internal / External Sidewall Marking Options

10. Auto-Adjustable Width Chuck

11. Belt Driven Center Conveyor

12. Entrance Conveyor with Luber / Barcode Reader

13. Auto-Position Center Grinder

14. Auto-Position Shoulder Grinders

15. Spindle Servo Motor &Gearbox

16. Frictionless Loadwheel Carriage

17. Mobile Panel